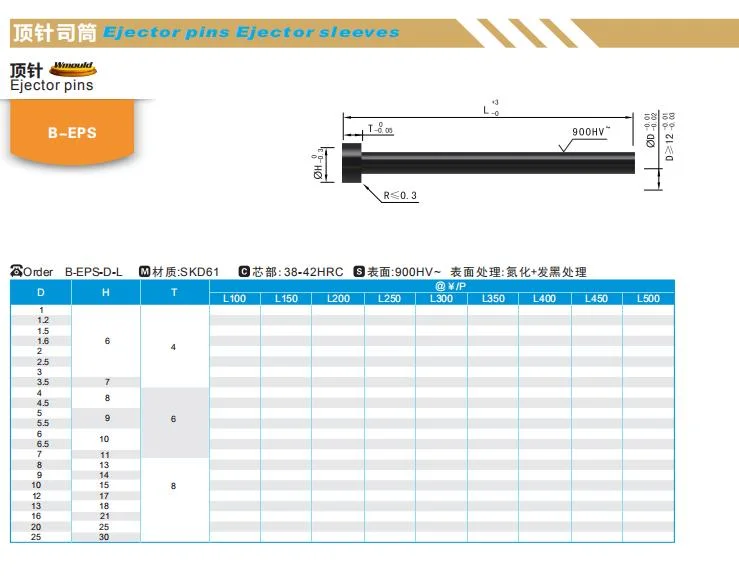

Wmould Plastic Injection Mold Parts Pre-Hardened Ejector Pin B-EPS Ejector Pin Manufacturer Mold Parts Mold Tooling

Welcome OEM/ODM Orders Product Description Factory show Quality Inspection Certification Customer&Exhibition show Packgi

Basic Info

| Model NO. | B-EPS |

| Usage | Plastic Injection Mould |

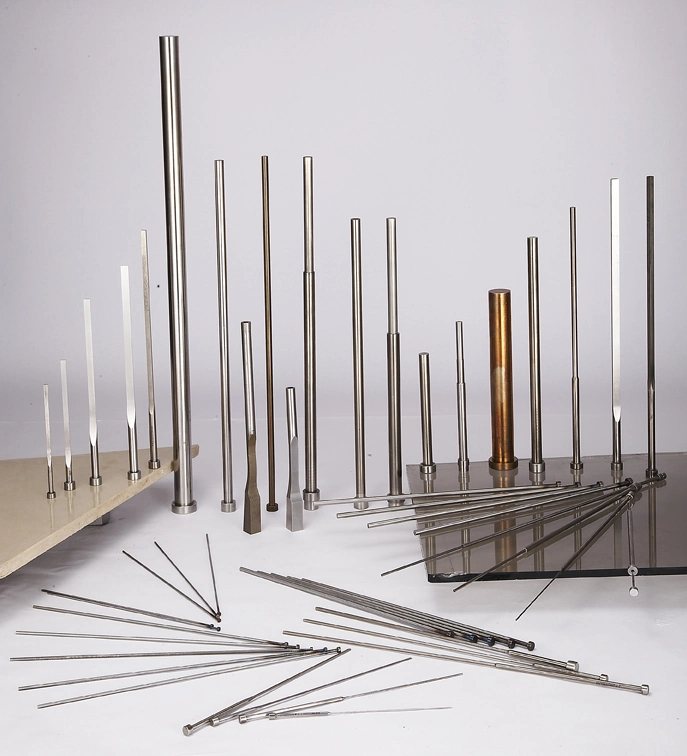

| Product Name | Ejector Pins |

| Transport Package | Shenzhen Port, Guangzhou Port and Another Port in |

| Specification | according to customer requirements |

| Trademark | wmould |

| Origin | China |

| Production Capacity | 1000 PCS Per Day |

Product Description

Welcome OEM/ODM Orders

Product Description

| Product name | Wmould Plastic Injection Mold Parts Pre-hardened Ejector Pin B-EPS Ejector Pin Manufacturer Mold parts mold tooling |

| Material | SKD61,SKH51, SKD11, S136 , SUJ2, Aluminum Alloy ect |

| Tolerance | Can be ±0.002mm,high accuracy |

| Processing step | material cutting→turning→milling→heat treatment→coreless grinding→wire EDM→surface treatment→polishing→inspection→packing&shipping |

| Surface treatment | Blackening, phosphating, pickling, electroless plating of various metals and alloys, TD treatment, QPQ treatment, chemical oxidation, anodizing, electrochemical polishing, electroplating, sand blasting, polishing, rolling, polishing, brushing, spraying |

| Processing equipment | CNC lathe, CNC turning milling grinding drilling machine,Wire E.D.M,PG ,Cylindrical internal grinding machine,Grinder,planer,spark Machines, |

| Inspection instrument | projector,height gauge,three dimensional measuring instrument,microscope,height gauge,thickness meters. |

| International standard | Non-standard and standard(DME,HASCO,DIN,MISUMI) |

| QC System | Pre-inspection, intermediate inspection, post-inspection, three procedures to ensure that each product is qualified |

| Quality assurance | 99.9% qualified |

| Delivery time | general 10-15 days,large QNT 1-2 month, |

| Shipment | international express(DHL FedEx TNT UPS EMS SF Express) |

| After-Sales Service | If product is damaged,refund or repair for customer,until the customer is satisfied |

| Sample | Sample can be provided. |

| MOQ | ≥1pcs |

Factory show

Quality Inspection

Certification

Customer&Exhibition show

Packging&shipping

FAQ

1. Are you a manufacturer or a trading company?We are direct manufacturer with over 18 years' export experience for precision parts, welcome to visit us.2. How can I get the quotation?Please contact our sales man with your demands,information include material,model number and any other special requirements.

3. Can you produce precise parts according to our drawing or our samples?Yes, we can produce parts according to your 2D or 3D drawings, and we can make measurement for your samples to make drawings for production.

4 . What is the quality guarantee?We will make 100% inspection before packing and delivery to make sure the products 100% meet your requirements.We will keep the production drawing and test report with 3 months, if you found any problems when received the parts, please contact us at the first time, we will give you a solution within 8 hours.

5. How do you guarantee the deliver time?We have independent PMC department to arrange the production plan.We have production meeting every morning to report the production progress and discuss the problems.We will make production progress report to you every week and take some pictures for your reference, that's you can know our production progress clearly.

Send to us