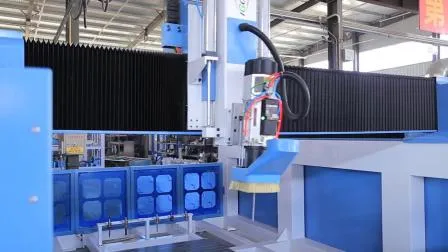

Portable Spray Polyurethane/Polyurea Coating Machine Spraying Machinery

Package size per unit product 750.00cm * 540.00cm * 1120.00cm Gross weight per unit product 139.000kg Portable Polyurea

Basic Info

| Model NO. | E3 |

| Application | Hardware Spraying Equipment, Plastic Spraying Equipment |

| Coating | Powder |

| Certification | CE, ISO |

| Method Type | Automatic |

| Condition | New |

| Power Source | 3-Phase 380V 50Hz Single Phase 220V 50Hz |

| Heating Hose Power | 2000W/15meters |

| Air Source | 0.3-0.8MPa≥0.9cbm/Min |

| Maximum Output Pressure | 20MPa |

| a and B Chemical Output Ratio | 1:1 |

| Product Type | EPS Packaging |

| Power (Kw) | 7.5kw |

| Whole Power | 12kw |

| Driven Mode | Pneumatic |

| Chemical Output | 2-12kg/Min |

| Transport Package | Wood Packing |

| Specification | 139kg |

| Trademark | Hightop |

| Origin | Shandong Province, China |

| HS Code | 8477800000 |

| Production Capacity | 10000/Year |

Packaging & Delivery

Package size per unit product 750.00cm * 540.00cm * 1120.00cm Gross weight per unit product 139.000kgProduct Description

Portable Polyurea Reactor PU Foam Spray Machine Polyurea Spray Machine Polyurethane Polyurea For Wall Roof Tank InsulationHightop fibreglass chop equipment for FRPs (fibre-reinforced plastics) is engineered with exclusive technological advancements toprovide unmatched durability and ease of use. Unique spray control technology delivers a superior mix of resin and fibreglass chop

strands for material efficiency and better working environments. Operators can maximise production capacity with a simple user

interface and tool-free catalyst adjustments.

| Item | Data |

| Heating power | 7.5kw |

| Driven mode | pneumatic |

| Raw output | 2~12kg/min |

| Maximum working pressure | 17Mpa |

| AB material output ratio | 1:1 |

| Max hose support | 90m |

Send to us