Steam/Oil/Electric Heating Jacket Q235 Q345 Ms Carbon Steel Glass Lined Tank for Methyl Tin Mercaptan Heat Stabilizer 181

Glass Lined Reactor special for making Methyl tin mercaptan heat stabilizer Part One: Chemical raw materials for making

Basic Info

| Condition | New |

| Shaft Seal | Packing Seal or Mechanical Seal |

| Overseas Service | Support |

| Overseas Aftersales | Support |

| Design and Manufacturer License | 1,2 and 3 Level Pressure Vessel License |

| Application 01 | Methyl Tin Mercaptan Heat Stabilizer |

| Application 02 | Methyl Tin Mercaptan PVC Heat Stabilizer |

| Application 03 | PVC 181 Methyl Tin Mercaptan Heat Stabilizer |

| Application 04 | Tin 181 PVC Stabilizer |

| Application 05 | Liquid 181 Tin PVC Stabilizer |

| Transport Package | Metal Frame |

| Origin | China |

| HS Code | 8479820090 |

| Production Capacity | 310 Sets Per Year |

Product Description

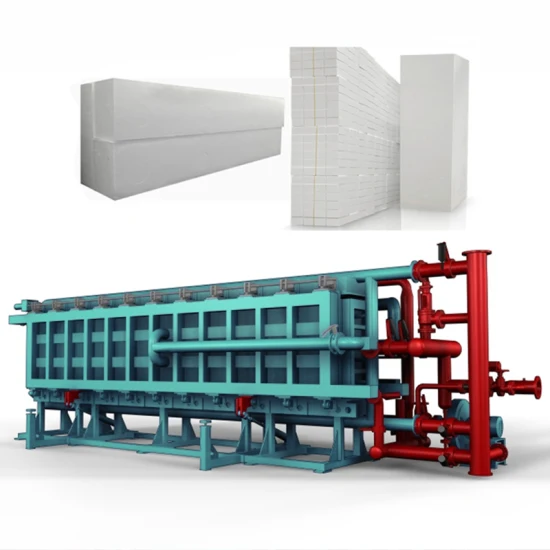

Glass Lined Reactor special for making Methyl tin mercaptan heat stabilizer

Part One: Chemical raw materials for making 181 Tin Pvc Heat Stabilizer:

1. Tin ingot

2. Monochloromethane

3. Tin tetrachloride

4. Tetramethylammonium chloride

5. Isooctyl thioglycolate

6.Ammonia

Part Two: Production process:

1. Intermediate synthesis:

Put metallic tin into the reaction kettle first, heat to dissolve, add monochloromethane, tin tetrachloride, and tetramethylammonium cyanide, and react for four hours. After the reaction is completed, the reaction product is moved to the distillation reactor for distillation, and the product is the intermediate.

The intermediate is a mixture of dimethyl tin dichloride and monomethyl tin trichloride. By adjusting the amount of tin tetrachloride added, the ratio of dimethyl tin dichloride and monomethyl tin trichloride in the intermediate is controlled to be around 75:25.

2. Synthesis of methyl tin mercaptan:

Put the intermediate and isooctyl thioglycolate into the reaction kettle while adding ammonia water dropwise. After the reaction is completed, wash with water (washing water can be added to the reaction kettle). After washing, use a filter to filter out the waste residue in the reaction product. After the distillation process, the water is evaporated, and finally the product methyl tin mercaptan is obtained. Through the sulfhydryl synthesis reaction, the main components of the finished product are:

(1) Isooctyl tin dimethyl dimercaptoacetate 75% CAS NO.: 57583-35-4

(2) Isooctyl tin monomethyl trimercaptoacetate 25% CAS No.: 57583-34-3

Send to us