Lightweight Panel Mould for EPS Fiber Cement Sandwich Panel/Partition Wall Panel Making Machine

Basic Info

| Model NO. | Customer Request |

| After-sales Service | Offer |

| Warranty | One Year |

| Type | Concrete Mixer |

| Shotcrete Type | Semi-Dry |

| Machining Process | Brick Production Line |

| Structure | Rotor Type |

| Productivity | 240m²/h |

| Feeding Height | 1400mm |

| Vibrating Amplitude | 2.4mm |

| Certification | ISO9001: 2000, CE |

| Condition | New |

| Color | Blue |

| High-Quality | 100 |

| Transport Package | Sea Transportation |

| Trademark | HAIYU |

| Origin | Shandong, China |

| HS Code | 84748090 |

| Production Capacity | 5set/Month |

Product Description

Product DescriptionEPS Cement Sandwich Panel is a kind of lightweight energy saving wall material, which uses cement calcium silicate or reinforced calcium silicate board as face panel, filled with cement, Expanded Polystyrene (EPS) foam particles as core material and forming by one time compound.

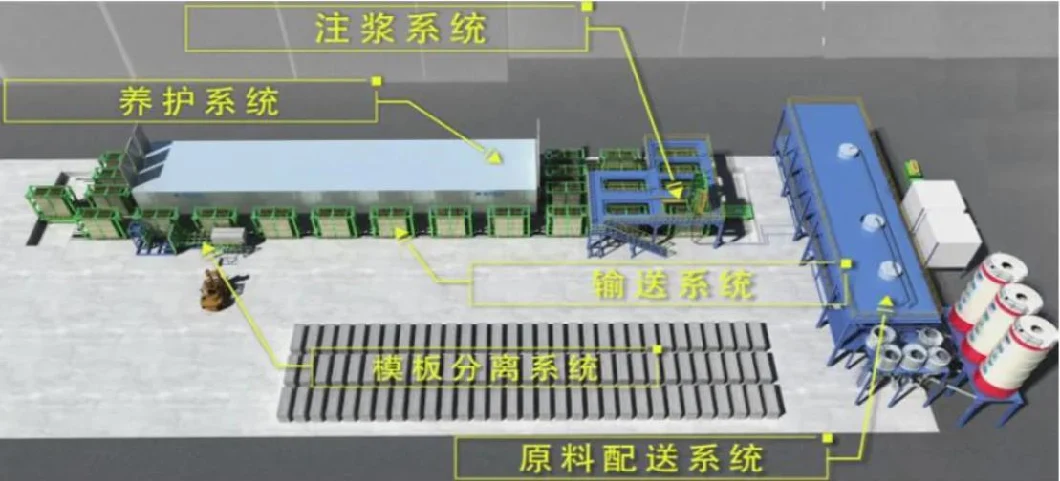

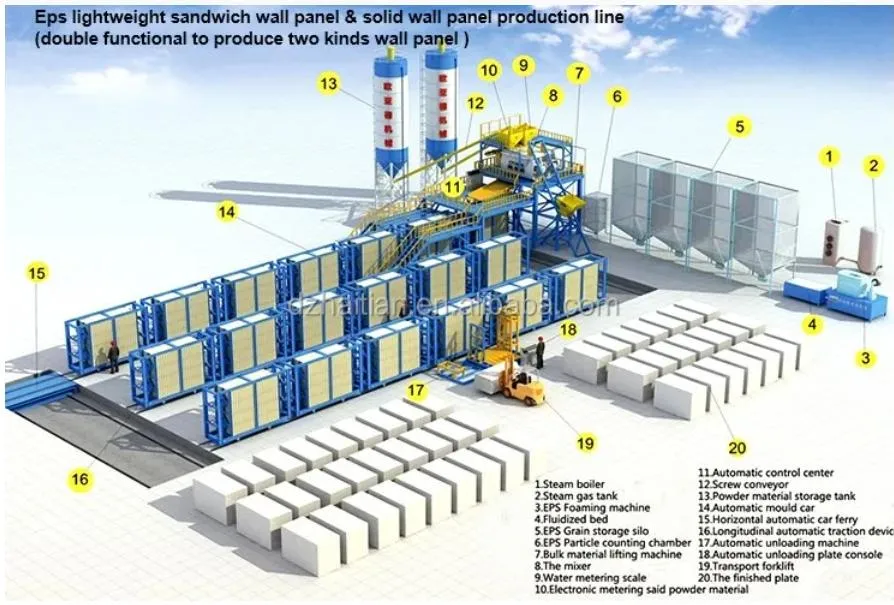

Automatic lightweight eps cement wall panel line

The EPS lightweight panel production line mainly have these parts foaming system, storage system, conveying system, measuring system, mixing system, casting system, demolding system. Demoulding, 20panels/time. So can save a lot of your labor cost.

After installation and commissioning, we will provide technical formula suitable with client's demand, ensuring clients can produce qualified finished products. Additionally, we will help local experienced engineers for one year to master the production process.Our professional sales team, designing team, manufacturing team, installation team, process team, service team, promise you a 100% perfect project.

| Machinery Parameters | |||

| Capacity | 20,000sqm~600,000sqm per year | ||

| Thickness | 50-200mm thickness. special sizes need to be customized | ||

| Length | 2440~3600mm | ||

| Width | 610mm | ||

| Raw materia | There are mainly two different types1. Cement+fly ash/eps/ceramsite/sand, etc (optional, can choose to add or not add)2. Fomed cement+additives | ||

| Finished board type | 1. Composite board/sandwich board, with surface board2. Lightweight solid panel, without furface board | ||

| Surface board types | 1. Calcium silicate board2. Fiber cement board3. Mgo board | ||

| Electrical | There are mainly two different types | ||

Main system of eps cement sandwich panel production line:

1.Mixing system (include mixer, platform);

-Cement and flyash will be metering and feeding into the mixer by cement screw conveyor pump, save labor and environmentally .

-Sand (or ceramsite /slag /pumice stone other agregate) and additives will be feeding into the mixer by lifting hopper.

1)Double-shaft mixer;

Capacity available :1.2/1.5/2.0/2.5/3.0/3.5 sqm Introduce:the mixer capacity is related to the mould car quantity. Features: the double shaft is to blend the raw material more even ,also save time .

When mould car qty over 10 units, we recommend to use the secondary mixing mixer. This can save time of 01st mixer, improve efficiency.

2)Platform

-Measuring platform,

-Mixing platform (necessary),

-Casting platform (necessary),

-Electric control cabinet platform ,

-Auxiliary Platform /Calcium Silicate Board installation platform

ps:Besides necessary platform , other platform we can equip as client requirement .

2.Material convey and feeding system:

Use industrial hose pump as grouting power, just need to connect a hose, one worker can easily finish the grouting work. High efficiency and clean at site.

3.EPS foaming system(include boiler, eps foaming machine);

Boiler supply heat, and eps foaming machine foam EPS particales into requried size.

Customer can also choose to buy EPS foam particales locally, to save equipemnt investmetn on this part.

4.De-molding machine:

High automatic level and just need one worker to operate the machine, panels in the whole mold car can be de-mold in several minutes! No damage to the eps sandwich wall panel, high efficiency.

5.Curing system

EPS Cement Sandwich Panels Applications:

-Non-load bearing interior & exterior wall panels, partition wall panels, floor panels, roof panels.

-Bathrooms, kitchens, garages, basements, prefabricated houses, family homes, dormitories, residences, apartments, luxurious villas, factory warehouses, production workshops, auxiliary plants, hotels, bars, shopping malls, restaurants, schools, hospitals, airports, etc.

non-load bearing parition wall panels in prefab buildings:

Exhibitions abroad

Company IntroductionDezhou Haitian Electromechanical Technology, founded in 1997, is a high-tech enterprise specializing in the construction of industrial intelligent equipment manufacturing, with mature equipment research and development, manufacturing and service experience. Its products are sold all over the country and exported to more than 80 countries and regions. The company is located in No. 956, Hongdu Road, Songguantun Street, Tianqu New District, Dezhou, with a registered capital of 52,040,800 yuan, covers an area of 73 mu and a factory area of more than 30,000 square meters. It has more than 240 employees, including more than 60 R&D technicians, 4 foreign experts and more than 30 senior and intermediate titles. Echelon of R & D technicians can tailor a variety of prefabricated building components and equipment for customers overall solutions, R & D design ability is the core competitiveness of the company. In 2017, the company and China Academy of Building Science jointly undertook the national 13th Five-Year Key research and development Plan green building and construction industrialization key special project "Key technology and assembly of Precast concrete component industrial production" (project number: 2017YFC0704000), the scientific research achievements identified as the international leading technology. The company has edited 3 national industry standards and participated in 11 national standards. The company has more than 100 patents, including 36 invention patents (11 have been authorized).

We supply technical supporting all the time.

Our salesman will be online for 24 hours.

You can visit us at any time.

We supply one year warranty for whole machine.

We supply free quick wear parts.

We supply low charge continue maintenance when warranty is expired.

We supply free training for end-users.