Wld6200 CE Car Painting Booth / Car Painting Machine in Philippines

Basic Info

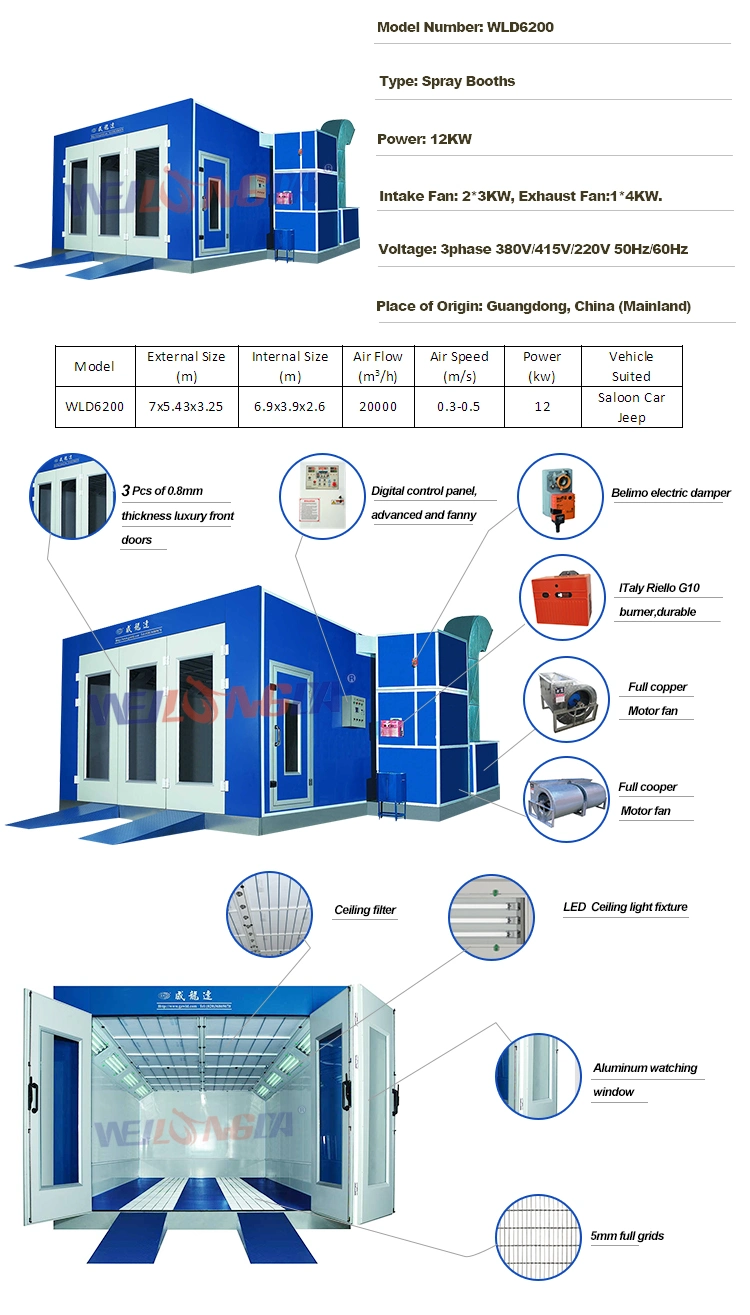

| Model NO. | WLD6200 |

| Coating | Powder Coating |

| Airflow Direction | Fully Undershot-type |

| Heating Mode | Diesel, Infrard, Natural Gas, LPG, Optional |

| Paint Mist Treatment | Dry-type |

| Condition | New |

| Internal Size | 6.9X3.9X2.6m |

| External Size | 7X5.43X3.25m |

| Air Flow | 20000m3/H |

| Air Speed | 0.3~0.5 M/S |

| Power | 12kw |

| Delivery Time | 7-10 Days |

| Heating System | Diesel Burner |

| Voltage | 380V/220V 3pH AC 50-60Hz |

| Color Choice | Red,Orange,White,Blue |

| Wall Panel | EPS, Rock and PU for Optional |

| Fan Type | Centrifugal Fan,Turbo Fan Optional |

| Basement Height | 300mm |

| Control Panel | Digital and Intelligent Control Panel |

| Vehicle Suited | Car and SUV |

| Air System Position | Right,Left, Can Be on The Top of Spray Booth |

| Transport Package | Export Standard |

| Specification | Economic Type |

| Trademark | WLD |

| Origin | Guangzhou, China |

| HS Code | 8419899090 |

| Production Capacity | 2, 000 Sets/Year |

Product Description

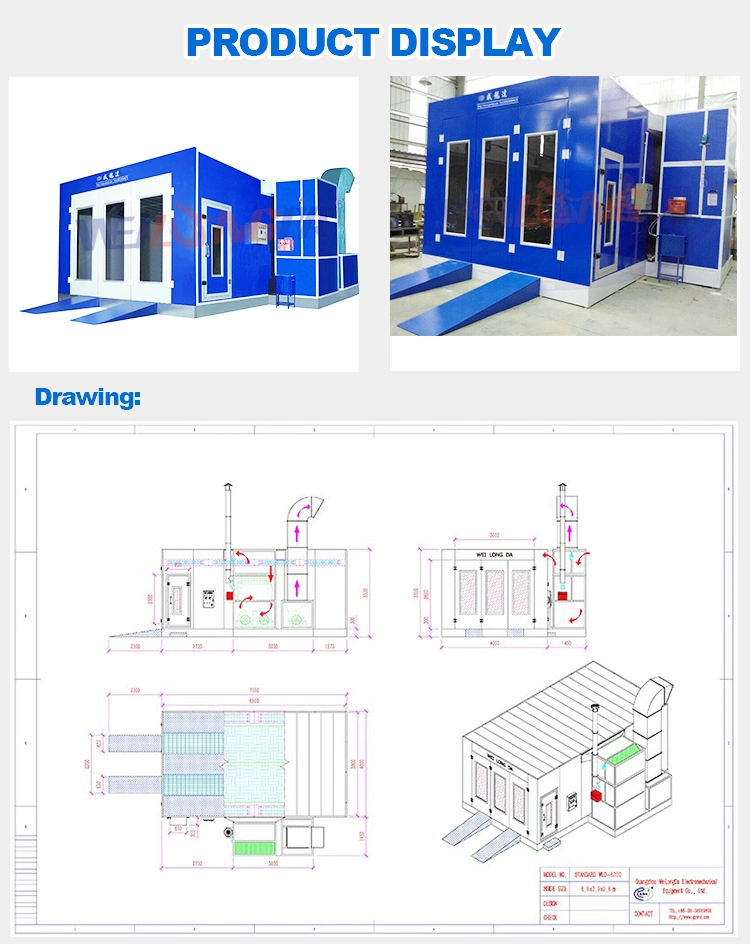

WLD6200 CE Car Painting Booth / Car Painting Machine In Philippines :- Wallboard: Sandwich style EPS (epispastics polystyrene) 50mm thickness. Galvanized steel roof panel.

- Basement: Galvanized steel sheet and square steel pipe construction. 2 rows of grids with floor filter & 3 rows of checkered plates. 2 pcs of ramps.

- Door: 3 pcs of luxury front doors with 0.8mm thickness colorful steel skin. Size: 3000(w) x 2600(h). 1 pc of emergency door. Watching window with aluminum frame.

- Air Circulation System: 2x3kw intake fan,1x4kw exhaust fan. BELIMO 20N electric damper.

- Burner: Italy Riello G10 diesel burner, 100000Kcal/h. The heating time 7-9min(20-60.C). Max. temperatureat 80.C. Fuel consumption is 4-5kg/vehicle.

- Heat Exchanger: Made of stainless steel. The heat exchange rate reaches 85%.

- Lighting System: Ceiling light has 24 pcs of 16w LED lamps. 800 Lux.

- Air Purification: Dual filtering structure. The primary filter can capture granules larger than 10μm. Ceiling filter capture granules bigger than 5μm. The air cleanliness in the working environment can reaches 98%.

- Pollution Control System: Multi-layer fiberglass filter.

| Model | External Size (m) | Internal Size (m) | Air Flow (m3/h) | Air Speed (m/s) | Power (kw) | Vehicle Suited |

| WLD6200 | 7x5.43x3.25 | 6.9x3.9x2.6 | 20000 | 0.3-0.5 | 12 | Saloon Car Jeep |

FAQ

Q1. What is your terms of packing?

A: Generally, we pack our goods by thicker bubble paper, some of them are packed by carton.Q2. What is your terms of payment?

A: By T/T, 30% as deposit for production, and 70% balance before delivery. We'll show you the photos of the products and packages before you pay the balance.Q3. What is your terms of delivery?

A: Normally our quotation is under FOB Guangzhou, but we also accept EXW, FOB, CFR, CIF, DDU. Q4. How about your delivery time?

A: Generally, it will take 10 to 15 days after receiving full payment. If your voltage is different from 380V/3PH/50Hz, the delivery time will be around 20 days for custom-made motors or electric components. Q5. Can you produce according to the technical drawings?

A: Yes, we can produce by your technical drawings or requirements. We can make drawings for you.Q6: How do you make our business long-term and good relationship?A1. We keep good quality and competitive price to ensure our customers benefit ;A2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Q7: Why choose WeiLongDa?

A1. Wallboard - All WLD spray booth wall panels are anti-fire EPS,foam density is 14kg/m²;

A2. Front door - with aluminum view window, made of 50mm EPS, 0.8mm galvanized steel with plastic spray. Front door is like a face, beautiful, strong, practical, leakproof, anti-rusting & long-lasting, it means your workshop will attract more business and you will spend less time and money on spray booth maintenance;

A3. Steel structure - 4000kg vehicle can safely get in and out of the booth without worried, no noise, vibration is minimized, no air leakage, dust free, clean and efficient, we use thick galvanized steel pipes to make our spray booth cabinet, so our cabinet is anti-rusting;

A4. Heat exchanger - 2 layers radia pipes structure with 2 wings welded by experienced skillful welder, it is high efficiency & safe;

A5. Motor fan - introduced from Simens technology with large air flow at low noise, high quality bearing, full cooper coils, rock wool sound proff cover;

A6. Components finishing - since Weilongda factory has its own powder coating facility, all components seen were with powder coated treatment. Strong anti-rusting finishing, not just good looking but also make a durable spray booth.

A7. Advantages of Weilongda control panel1) dust free2) user can intuitively see the booth actual operation status from the panel3) spray temperature and baking temperature were set in internal memory, no need to reset temperature when change the mode 4) digital pressure display with over pressure alarm5) over heat fire alarm system6) we offer 1 year warranty, life-long maintenance for our booth;

A8. Small details1) hinge type ceiling filter frame, one person can handle changing filter2) flter is self sealing no need screw to fix3) fan filter is easy to access with small door and handle4) front door locking pin with position locking5) infrared lamp with rock wool isolation6) infrared lamp install with isolation distance7) infrared lamp with door open security sensor switch8) infrared lamp with wire entrance prastic screw.