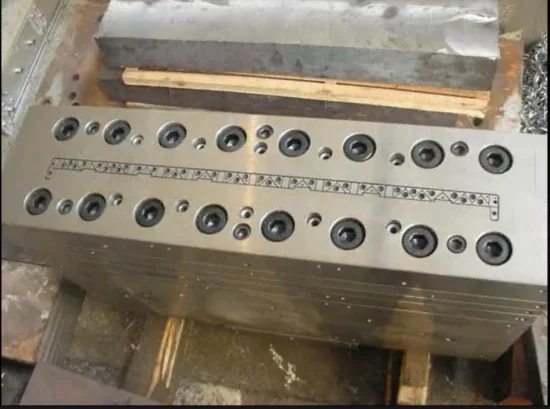

Light Weight EPS PS Polystyrene Foam Baseboard Exterior PS Skirting Moulding Extrusion Mould

Basic Info

| Model NO. | 50mm |

| After-sales Service | One Year |

| Warranty | One Year |

| Product Type | PVC Profile |

| Screw | Double-Screw |

| Automation | Automatic |

| Computerized | Computerized |

| Certification | CE, ISO9001:2008 |

| Customized | Customized |

| Projection Solution Capacity | Graphic Design, 3dmodel, Total Solution for Projec |

| Process | Extrusion Moulding |

| Application | Apartment, Decorate The Windows |

| Feature | Eco-Friendly, High Durability, Smooth Operation |

| Type | OEM Extrusions Plastic Profiles |

| Sharpe | Customized as Your Requirements |

| Technique | Extrusion or Co-Extrusion Profile |

| Die Head | 2Cr13 Mould Steel, 3Cr13 Mould Steel, 3cr17 Steel |

| Heating Plates | Cast-Aluminium |

| Calibrator | 2Cr13 Mould Steel, 3Cr13 Mould Steel, 3cr17 Steel |

| Suface Treatment | Mirror-Polished |

| Application for | Indoor Construstion, Decorative Building |

| Accessories | Removable Location Pin, Detachable Tread Insert |

| Product Material | Steel |

| Forming Method | Extrusion Mold |

| Transport Package | Wooden Case |

| Specification | 800mm |

| Trademark | Hannshine |

| Origin | Shanghai China |

| HS Code | 8477900000 |

| Production Capacity | 100000 |

Product Description

Customized Light Weight EPS PS Polystyrene Foam baseboard Exterior PS skirting Moulding factory price

Our Advantages1. DIE HEADUse the removable positioning device,making it easier to disassemble. Precise material flow control and stable extrusion.The hidden heating design has increased the brightness pf the product surface.The special balance of the pressure holes has lowered the rejection rate. customized PE single cavity Wall Panel Extrusion moldtool making2. CALIBRATORThe automatically adjusting positioning key gives it a precise size .The tapered design of the styling sets has increased the production speed greatly.The inlet end is independent vacuum and shapes well.The camber adjusting device ensures that the line is straight3. WATER TANKThe combination design of eddy current and spray makes it cools fastThe self-adjusting water tank panels are easy to adjust.The stainless steel frame type system can prevent damage.The special in fluent distribution gives it a cooling balance.4. Mouth mold, mold core, finalize the design mode, finalize the design mode and one end of the mold core connection with convex sets, finalize the design mode on the other end of the end face with discharging mouth, name and address of convex surface is equipped with inlet, feed port and discharging port connected to form a fixed mold, the mold core including core rod, cross arm,connection on both ends of the transverse arm fixed arm, at the bottom of the plug connection in central cross arm, has purethrough its internal mold core The water cooling flow channel, the boss is provided with a through groove for the arm through, anda gap is arranged between the inner wall of the through groove and the outer wall of the arm. Using the structure, the invention has the following advantages :1. Avoid the roughness of the product inner cavity caused by the high temperature of the mold in the forming process, improve the smoothness of the product inner cavity and improve the product performance; 2.the fixed arm of the mold core and the fixed seat of the mold are clamped and firmly connected.Product Parameters| No | Product Name | Product Material | Configuration |

| 1 | Die mold | 3Cr13 | 1 or multi-cavity |

| 2 | Heating bands | Cast-aluminium/Stainless steel | / |

| 3 | Calibrator | 3Cr17 | 1-5 240mm |

| 4 | Water tank | Steel | / |

| 5 | Water stop sheet | Steel | 4-24 sheets |

NO. | Test Items | Technical Requirements | Units | Measured Value | Single Conclusion |

1 | Extrusion speed | 0.8-1.8 | m/min | 0.87 | conform |

2 | Yield | >98 | % | 99 | conform |

3 | Thickness deviation | <1.2 | mm | 0.24 | conform |

4 | Water absorption | ≤3.0 | % | 1.0 | conform |

5 | Density | ≥0.85 | g/ cm³ | 1.38 | conform |

6 | Tightness | No leakage | / | conform |

Q1. Are you trading company or manufacturer ?

A: We are factory.Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.Q3. What is your terms of delivery?

A: FOB, CIF, CFR, EXWQ4. How about your delivery time?

A: Generally, it will take 10 to 30 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.Q7. What products do you have?

A: PVC, PP, PA, ABS, PE, Door seal series, Plastic co-extrusion, Plastic cladding, Multi-color co-extrusion, Plastic products, LED Lampshade, Baby bed protect strip, Plastic electrical cable trunking best price various size pvc cable trunking; Extrusion molds, Stamping molds, and other types of rubber and plastic molds.