EPS Shape Moulding Machine

Main features 1. The machine adopts PLC and touch screen and advanced moulding technique and can produce various shape o

Basic Info

| Model NO. | FAV1200E, FAV1400E, FAV1750E, |

| Model Number | Vsm100-200t |

| Plastic Type | EPS |

| Certificate | CE/ISO9001 |

| Mould Dimension | 1800*1600mm |

| Max Product Size | 1610*1400*330mm |

| Connected Load | 23.6kw |

| Machine Size | 5100*2610*3800mm |

| Cycle Time | 120-190s |

| Transport Package | 20ft Container, by Sea, by Train, by Truck |

| Trademark | VST |

| Origin | Zhejiang, China (Mainland) |

| Production Capacity | 20units/Month |

Product Description

Main features1. The machine adopts PLC and touch screen and advanced moulding technique and can produce various shape of EPS products;

2. The machine adopts pressurized filling, featuring high speed and full feeding. Totally 25 to 37 automatic filling guns can be installed;

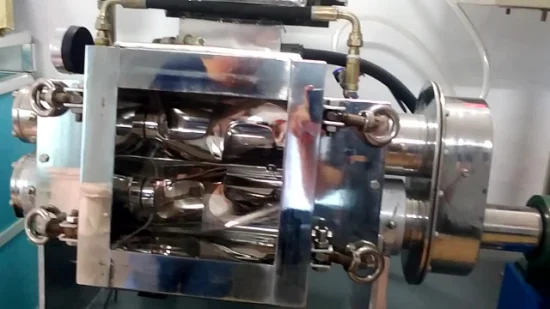

3. The machine adopts digital coder to control mould opening and closing stroke, controlled by PLC and easy to adjust; Mould opening and closing is actuated by hydraulic system;

4. The vacuum system can accelerate moulding speed, reduce cooling time and decrease moisture content of the product;

5. Hydraulic systems adopts differential fast device, improve the speed of moving mould journey to a maximum ofabout 200mm per second, saving energy comsumption over 40%.

6. Most of the main component are of world-famous brand, with reliable performance, stable quantity, long service life and low maintenance cost;

7. Automatic shape moulding machine with vacuum, the body of machine is welded steel plate, greatly improve the steel and hardness of the whole machine.

8. The screen adopts human interface design with easy opration and parameters setting.

9. The horizontal double switch chamber of the machine adopts material switch control system, greatly reduced as a result of raw materials result in waste probability.

10. The machine sets up particular drainage, vacuum system, meanwhile, improve the capacity drainage, vacuum system, meanwhile, improve the capacity of drainage.

11. Vertical vacuum chamber with spray devices, greatly improve the efficiency of the vacuum.

| TECHNICAL DATA | |||||||

| Item | Unit | VSM100T | VST120T | VST140T | VST160T | VST175T | VST180T |

| Mould Dimension | mm | 1000*800 | 1200*1000 | 1400*1200 | 1600*1350 | 1750*1450 | 1800*1600 |

| Max Product Dimension | mm | 800*600* 330 | 1000*800* 330 | 1200*1000* 330 | 1400*1100* 330 | 1550*1200* 330 | 1610*1400*330 |

| Stroke | mm | 210-1360 | 210-1360 | 270-1420 | 270-1420 | 270-1420 | 220-1370 |

| Steam Entry | mm | 50 | 50 | 65 | 65 | 65 | 65 |

| Steam Consumption | Kg/cycle | 6 | 7 | 9 | 10 | 10 | 11 |

| Water Entry | mm | 50 | 50 | 65 | 65 | 65 | 65 |

| Cooling water Consumption | Kg/cycle | 40-120 | 45-138 | 50-150 | 55-180 | 60-190 | 80-200 |

| Compressed air entry | mm | 25 | 40 | 40 | 40 | 40 | 50 |

| Compressed air consumption | M³ /cycle | 1.2 | 1.5 | 1.8 | 2 | 2 | 2.2 |

| Vacuum pump capacity | M³ /h | 165 | 165 | 230 | 280 | 280 | 280 |

| Connected load | Kw | 10.6 | 10.6 | 14.1 | 19.6 | 19.6 | 23.6 |

| Overall dimension | mm | 4500*1640* 2700(mm) | 4500*1840* 2900(mm) | 4600*2140* 3100(mm) | 5000*2300* 3400(mm) | 5000*2450* 3500(mm) | 5100*2610*3800(mm) |

| Machine weight | Kg | 4500 | 5200 | 5700 | 7000 | 7500 | 8000 |

| Cycle time | s | 60-90 | 60-100 | 60-150 | 90-160 | 90-160 | 120-190 |

Send to us