EPS Shape Moulding Machine for Polystyrene Foam Fish Box Making

Basic Info

| Model NO. | ESS810-1820S(SMED) |

| Customized | Customized |

| Transport Package | Ocean Shipping |

| Trademark | EPSOLE |

| Origin | China |

| Production Capacity | 150 Set / Year |

Product Description

Technical Data

| Machine Type | SMED (SngleMinute Exchange of Die) | |||||

| Item | Unit | ESS1214S/Q/E | ESS1417SQ/E | ESS1618SQ/E | ||

| Outer Diameter | mm | 5363x3310x4852 | 5363x3610x5152 | 5363x3710x5352 | ||

| Mould Size | mm | 1200x1400 | 1400x1700 | 1600x1800 | ||

| Max.Product Height | mm | 350 | 350 | 350 | ||

| Mould-Open Distance | mm | 1200 | 1200 | 1200 | ||

| Guide Pillar | Outer Diameter | ¢ | 80 | 80 | 100 | |

| Qty | pcs | 4 | 4 | 4 | ||

| Hydraulic Cylinder | Inner Diameter | ¢ | 125 | 150 | 150 | |

| Stroke | mm | 1200 | 1200 | 1200 | ||

| Lock force | bar | 29437 | 42390 | 42390 | ||

| Material Hopper | Volume | L | 145 | 145 | 145 | |

| Qty | pcs | 2 | 2 | 2 | ||

| Steam | Inlet | DN | 100 | 100 | 100 | |

| Mould Inlet | DN | 65x2 | 50x4 | 50x4 | ||

| Pressure | bar | 2.5 | 2.5 | 2.5 | ||

| Consumption | Kg/cycle | 6 | 7.5 | 9 | ||

| Cooling Water | Inlet | DN | 80 | 80 | 80 | |

| Mould Inlet | DN | 50 | 50 | 50 | ||

| Pressure | bar | 4 | 4 | 4 | ||

| Consumption | Kg/cycle | 40 | 50-120 | 60-160 | ||

| Vacuum | Connector | DN | 100 | 100 | 100 | |

| Drainage | DN | 100 | 100 | 100 | ||

| Compressed Air | High Pressure | Inlet | DN | 65 | 65 | 65 |

| Pressure | bar | 4 | 4 | 4 | ||

| Low | Inlet | DN | 50 | 50 | 50 | |

| Pressure | Pressure | bar | 5 | 5 | 5 | |

| Hydraulic | VolumeMotor | Kw | 7.5 | 11 | 11 | |

| L | 400 | 400 | 400 | |||

Detailed Photos

Hydraulic System:

*Adopt famous brand hydraulic components, differential pressure system design, can achieve high speed, low noise operation, the fastest mold opening and closing speed can reach 350mm/sec, can achieve high speed and efficient stable operation;*Two-point mold opening and closing, the latest mold clamping technology and mechanism, can stabilize the mold clamping pressure, the equipment is not easy to leak during production, and effectively improve the energy consumption (steam) utilization rate.Pipeline System:*The inlet, outlet and diameter of the valve of each pipeline system are optimized, so as to minimize the waste of energy consumption and increase the reaction speed;*The design of cooling pipe makes the water cooling fast and efficient. The mold cavity copper tube ring design makes the product contact surface more extensive, the cooling is more sufficient, and the product surface is smoother and smoother

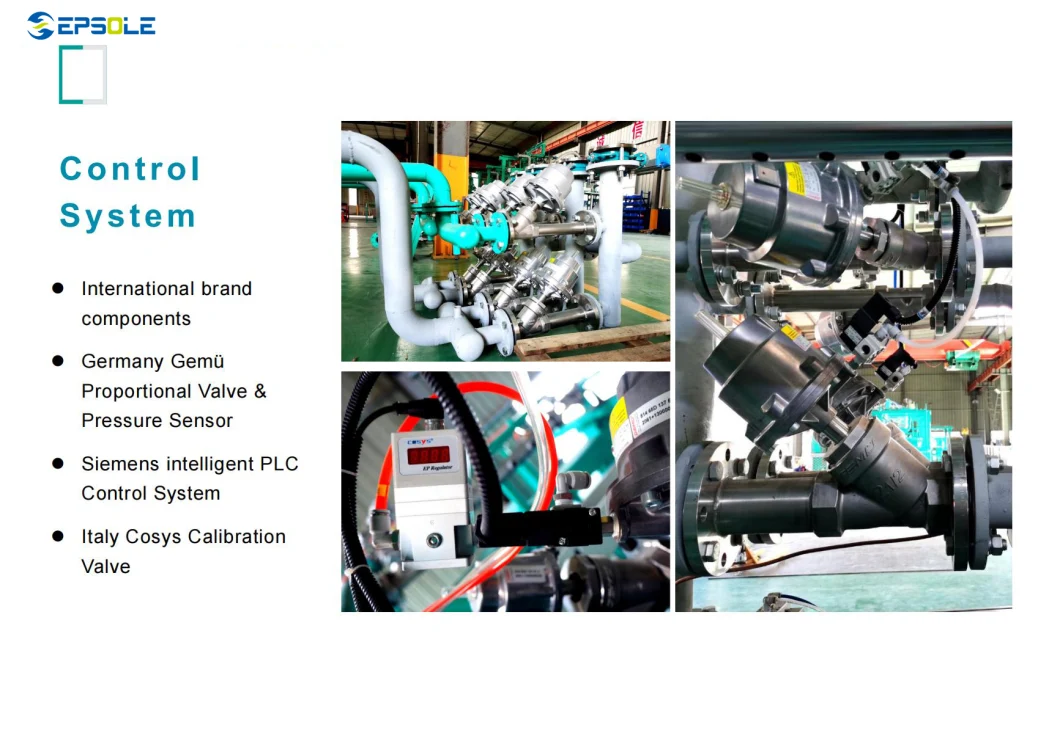

Molding System:*Apply electric digital proportional valve: adopt imported electric digital proportional valve with linear position sensor to efficiently and accurately control the proportional opening of the angle seat valve and combined with the digital pressure sensor, so that the mold cavity pressure can be linearly stable, changed traditional equipment Analog control of door open and close two switch ways, with imported valve brands of quality guarantee and stable performance, while effectively saving steam and other energy consumption;*EPS molding machine the latest heating system bypass pipeline, can effectively shorten the molding time and Reduce steam energy consumption

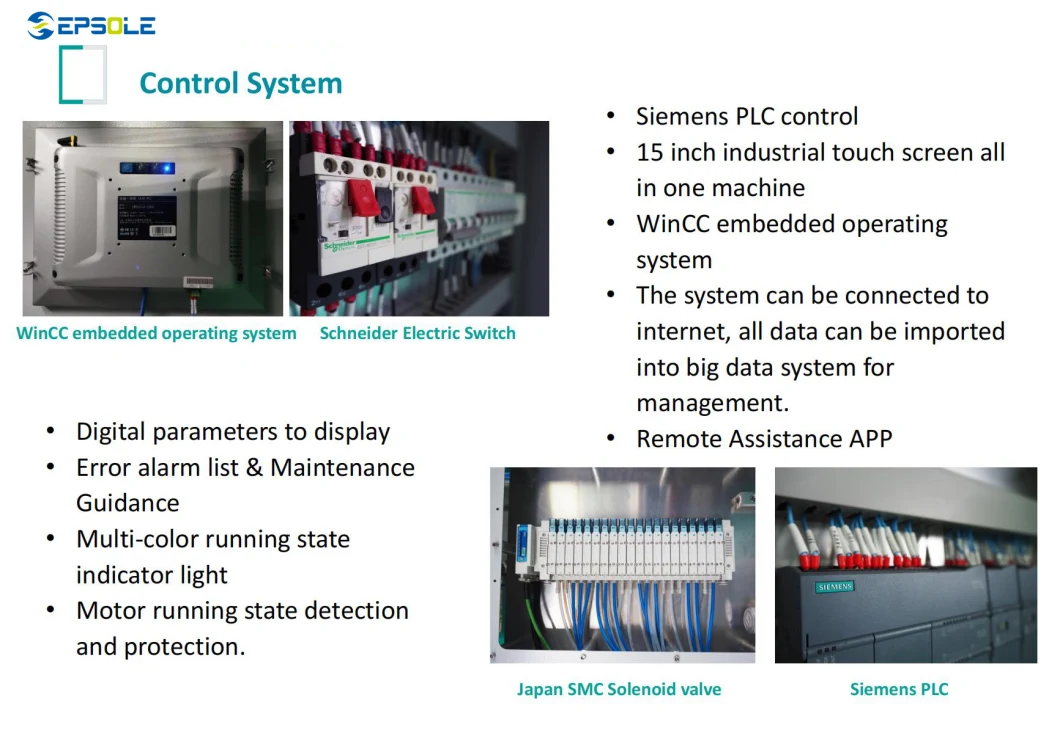

Control System:*Adopt Siemens intelligent control system and humanized windows system operation interface to make the operation more convenient and intelligent;*The imported electric proportional valve plus linear position sensor and pressure sensor are used to efficiently and perfectly cooperate with the control system to make the feeding, heating, blowing, water cooling and other work more accurate, stable, reliable and efficient;*The latest production molding technology makes it convenient and efficient control equipment to effectively improve production efficiency

production process

1.

Q: Where is your company located? How can I visit there?

A: Our factory is located in Hangzhou City, Zhejiang Province, China. Welcome to visit us.

2. Q. Do you have some videos where we can see the line producing?

A: Yes, we can provide some videos for reference.

3.

Q: What's the MOQ?

A: Our MOQ is 1 Set.

4.

Q: Can I have my own customized product?

A: Yes. Your customized requirements for color, logo, design, package, carton mark, your language manual etc. are very welcome.

5.

Q: Can you produce according to the samples?

A: Yes, we can produce mold by your samples or technical drawings.

6.

Q: What's the delivery time?

A: Generally, it will take 20 to 60 days after receiving your advance payment. The specific delivery time depends on the items and

the quantity of your order.

7.

Q: What is the payment terms?

A: T/T, L/C, D/P at sight

8.

Q: How does your factory carry out quality control?

A: We attach great importance to quality control.Every part of our products has its own QC.

9.

Q: What certificate do you have?

A: We have TUV, CCC, CE (EN71, EN14765), SGS, ISO9001 etc. Also we can apply any certificate if you need if the qty is OK.